Automatic Weighing And Packing Machine In In Chemical Industry For

Bulk Bag 50 Kg

Brief Introduction

Heavy bag granule automatic high-speed packaging machine is a new

type of packaging machine, which is developed for the packaging of

large bag granule materials in chemical, feed, grain, seed and

other industries. It has functions of automatic weighing, automatic

bagging, automatic filling, automatic package delivery and

automatic sealing. It can work with various granular and sheet

materials and equipment to realize the production of large-scale

packaging and heavy-bag packaging.

Scope of application

Particles, sheet materials (such as polyethylene, polypropylene,

polyvinyl chloride, PVC, PVA, etc.). In the process of production,

it realizes the full automation of bag supply, bag taking, bag

opening, bag bagging, metering, filling, bag unloading, clamping

shaping, folding and sealing, etc.

Technical Parameters

| No. | Item | Parameter |

| Material of premade bag | Premade PP woven Bag/Lamilated film |

| 1 | Packaging specification |

10kg-50kg

|

| 2 | Speed | 6-10 bags/min(regarding to different size); |

| 3 | Weighing accuracy | 0.2-0.5% |

| 4 | Power supply | 380V±10% 50Hz 14 KW |

| 5 | Machine weight | 2000kg |

| 6 | Machine size | 5700*2800*4900mm |

| 7 | Air supply source | 0.6MPa, 0.5m3/min |

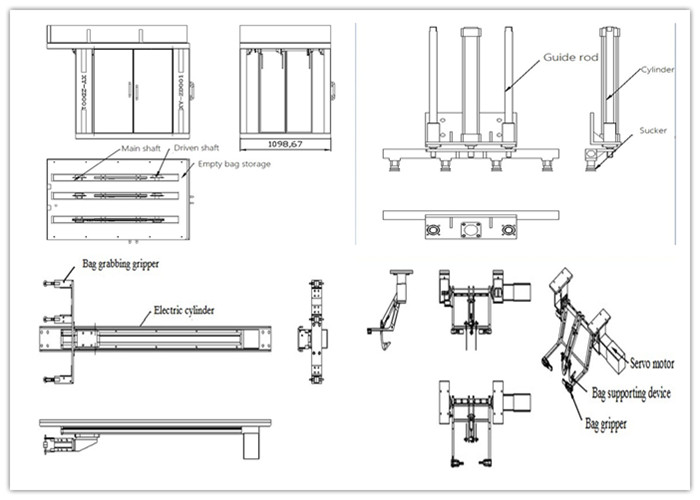

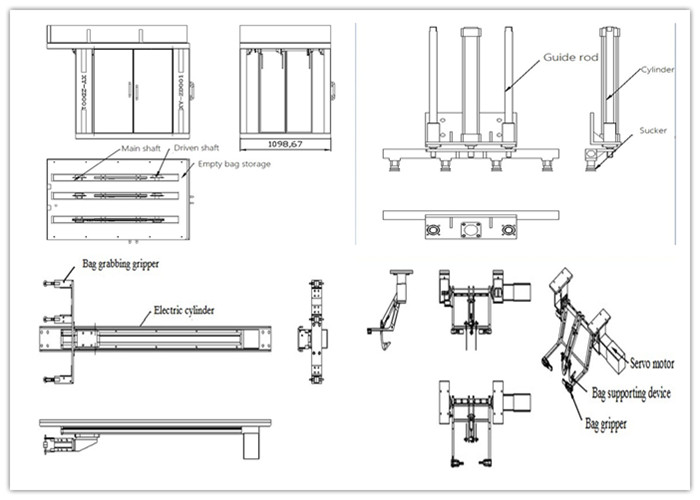

1.1 Packaging Unit

a. Hopper:0.3m³ Cone Type hopper, equipped with function of

material level alarm

b. Measuring Scale: High accurate packaging, three-sensor location

weighing structure, packaging speed over 700bags/h

c. Bag storage: 200-400 empty bags storage.

d. Bag Holding Type: mechanical arm fetching

e. Bag Sealing Type: fully automatic bag thread stitching or heat

sealing or other sealing type customer required.

f. Repair Platform: Lade stand, anti-slip platform and safety

railing

1.2 System equipment meets engineering condition &public use.

(1) Electricity:220/380V,50Hz

(2) Power:14kw

(3) Air Supply Pressure:0.5-0.7MPa

(4) Air Consumption:1.8Nm³/min

(5) Temperature:-15℃-45℃

1.3 Machine Main components

a. Empty bag storage

b. Empty bag taking unit

c. Bag management unit

d. Bag sending unit

e. Bag upper unit

f. Bag clipping and material filling unit

g. Bag holding unit

h. Bag mouth guiding unit

i. Heat sealing / bag sewing station

j. Stand-up bag conveyor

k. Electrical control section

Machine main parts list (subject to actual configuration)

| No. | Name | Brand |

| 1 | Vacuum pump | Shanghai Zhongde |

| 2 | Cylinder | Japan SMC |

| 3 | Solenoid Valve | Japan SMC |

| 4 | Other pneumatic components | Japan SMC |

| 5 | Normal Motor | CPG |

| 6 | Servo Motor | Delta (Taiwan) |

| 7 | Heat sealing head | Dechao |

| 8 | PLC | Omron |

| 9 | Touch Screen | Weinview |

| 10 | Inverter | Delta (Taiwan) |

| 11 | Switching power supply | Schneider (France) |

| 12 | Switch | Schneider (France) |

| 13 | Air switch | Schneider (France) |

| 14 | AC contactor | Schneider (France) |

| 15 | Motor circuit breaker | Schneider (France) |

| 16 | Thermal relay | Schneider (France) |

| 17 | Limit switch | Schneider (France) |

| 18 | Photoelectric | SICK |

| 19 | Load cell | |

Machine Features

1. The control parts use Siemens PLC and Weinview 10-inch color

touch screen, which has advantages of simple operation and

stability.

2. The pneumatic part adopts AirTAC magnetic valve, oil-water

separator and cylinder.

3. The vacuum system adopts German FESTO magnetic valve, filter,

digital vacuum pressure switch.

4. On all actuating mechanism, there is magnet switch or

optoelectronic switch as the detection unit, which is safe and

reliable.

Working Process

Automatic bag seizing

Automatic bag opening

Automatic bag feeding & material auto filling

Bag automatic transferred by the conveyor

Auto bag sewing / heat sealing (folded)

Finished bag

Packaging

Film wrapped and packed in fumigation wooden box.

Shipping:

* Upon receipt of delivery payment, delivery date will be in

3-15days

* By Air, by Sea or by Express (DHL etc.)

* Shipment cost will depend on the destination, shipment way,size

and the weight of the goods.

FAQ

Q: Are you trading company or manufacturer?

A: We are manufacturer with trade team for international service.

Q: How long is your delivery time?

A: Normally 60 days after confirmed order. 45 days could be

available in low season for some items (during May to July), and 85

days during new year and hot season (Jan to March).

Special cases need discuss.

Q: How do we test your machinery?

A: When the machine complete manufactured, we will send video for

check, and you also can come to our factory to test and learn how

to operate it.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 30% T/T in advance, balance before shipment.