High Speed Feed Pellets Packing Machine Bagged Rice In Grain

Industry

Application

Widely used in: grain (corn, rice, seeds, miscellaneous grains,

etc.), fertilizer (compound fertilizer, compounding method),

industrial plastics (carbon black particles, plastic granules),

chemical building materials (granular sand, granules, pebbles,

etc.) granules Quantitative filling of materials. For example: 10

kg bagged rice, 25 kg bag, 50 kg bag, etc.

Brief Introduction

Our new packaging machine unit designed for large bag of granule,

powder materials in chemicals, fertilizer, feed, grain, seeds,

food, rubber & plastic and other industries which has functions of

automatic weighing, bag clipping, filling, bag sending, bag sealing

etc. It can be connected with next steps equipment like palletizing

robot etc. to realize large-scale package and unmanned operation of

the stacking.

Technical Parameters

| Model Series | SXP50G |

| Packable Products | granules/ powders/flake particles |

| Bag Type | PE bags/ aluminum foil bags/ woven bags/ paper bags/ paper-plastic

composite bags etc. |

| Roll Film | Diameter of roll film≤1500mm,

inner tube of roll film: 150mm (6 inches) |

| Empty Bag Size | L(500-750mm), W(320-420mm) |

| Packaging Weight | 20-50 kg/bag |

| Packaging Speed | 300~600 bags/h |

| Power | 3 kW |

| Air Consumption | 200 NL/min |

Each Parts Introduction

- Weighing Machine: The part in contact with the material is made of

304 SS, other parts use carbon steel which sprayed with plastic.

Metering speed: weighing controller and sensor, reserved for dust

removal interface.

- Empty bag storage: The part in contact with the material is made of

304 SS, other parts use carbon steel which sprayed with plastic.

Electric power, reducer motor system.

- Bag upper unit and Bag holding & guide unit: Delta servo drive

system

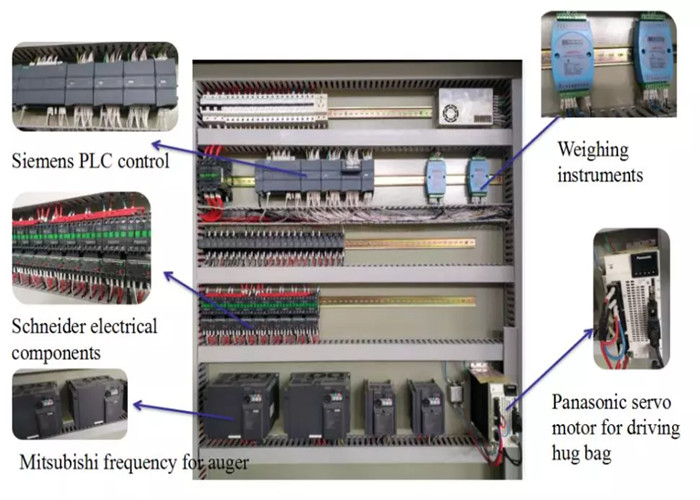

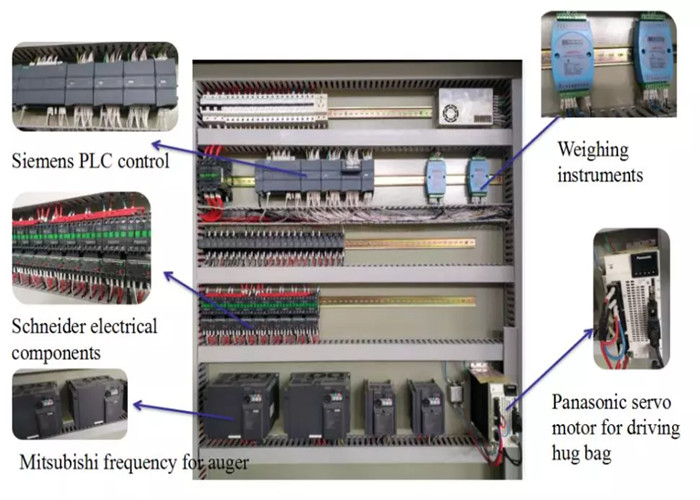

- Whole control cabinet: Self-developed patent system, widely used in

automatic packaging machines, and gained a good reputation. Germany

Siemens PLC control system and software system, France Schneider

Electric and other high-end configurations. Germany Sick

photoelectric control system, wire and cable and bridge wiring.

- Bag sewing machine / Heat sealing machine: suitable for open mouth

bag of woven bag, plastic bag, paper bag etc.

- Stand-up bag conveyor: Made of carbon steel + PVC belt + stainless

steel baffle guardrail, reducer motor system, Germany Sick

photoelectric control system, etc.

- Platform, guardrail, ladder: Carbon steel spray

Machine main parts list (subject to actual configuration)

| No. | Name | Brand |

| 1 | Vacuum pump | Shanghai Zhongde |

| 2 | Cylinder | Japan SMC |

| 3 | Solenoid Valve | Japan SMC |

| 4 | Other pneumatic components | Japan SMC |

| 5 | Normal Motor | CPG |

| 6 | Servo Motor | Delta (Taiwan) |

| 7 | Heat sealing head | Dechao |

| 8 | PLC | Omron |

| 9 | Touch Screen | Weinview |

| 10 | Inverter | Delta (Taiwan) |

| 11 | Switching power supply | Schneider (France) |

| 12 | Switch | Schneider (France) |

| 13 | Air switch | Schneider (France) |

| 14 | AC contactor | Schneider (France) |

| 15 | Motor circuit breaker | Schneider (France) |

| 16 | Thermal relay | Schneider (France) |

| 17 | Limit switch | Schneider (France) |

| 18 | Photoelectric | SICK |

| 19 | Load cell | |

Machine Features

1. PLC control system with low failure rate and higher reliability.

2.The host adopts fast and the slow inverter controls material

filling.

3. It has automatic storage of production information.

4. The operating parameters can be stored for later use, avoiding

recalibration when changing materials cyclically.

5. Accurate measurement accuracy and easy equipment cleaning, no

blocking.

Working Process

Automatic bag seizing

Automatic bag opening

Automatic bag feeding & material auto filling

Bag automatic transferred by the conveyor

Auto bag sewing / heat sealing (folded)

Finished bag

Packaging

* Machine packing inside is plastic films and outside is fumigation

wooden case.

* Our wooden case is very strong; it can bear long time shipping on

the sea.

* And machine with preservative film, it can stop the salt sea

water enter into the machine and make the machine corrosion.

Shipping:

* Upon receipt of delivery payment, delivery date will be in

3-15days

* By Air, by Sea or by Express (DHL etc.)

* Shipment cost will depend on the destination, shipment way,size

and the weight of the goods.

Service Environment

It shall be avoided to use the machine in the working environment

where there is corrosive, combustible gas or heavy powdery dust, it

shall be avoided to use the machine in the place with temperature

over 40℃, and shall be avoided to use it in the place with too high

relative ambient humidity (>85%HR).